What is Sunrise 2027?

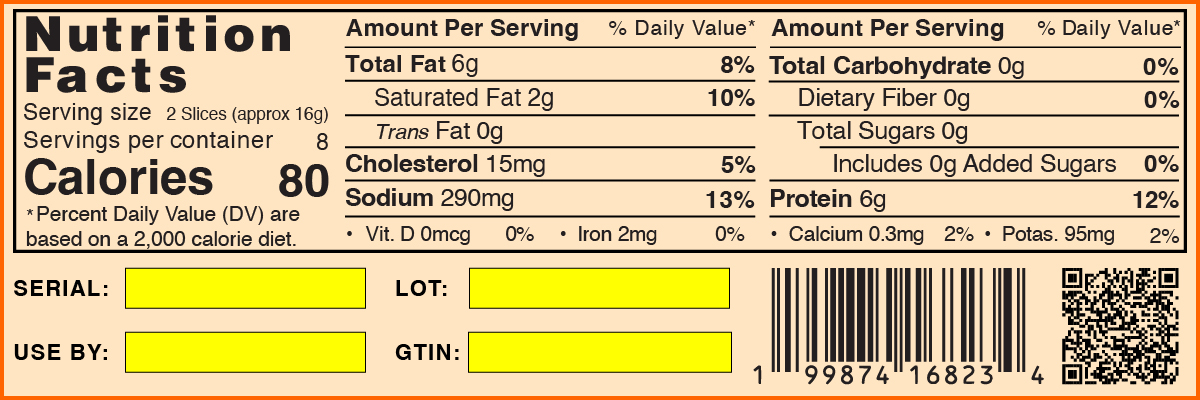

Sunrise 2027 is a global movement led by GS1 to enable 2D barcodes to be scanned at point-of-sale (POS) systems worldwide. Unlike the traditional 12-digit UPC that only identifies a product, 2D barcodes can store exponentially more information, including:

- Traceability Data: Batch and lot numbers, expiration dates, and serial numbers.

- Regulatory Compliance: Support for food safety mandates like FSMA 204.

- Consumer Engagement: Direct links to web content, sustainability stories, and digital coupons via the GS1 Digital Link.

Why Digital Printing is Critical

Sunrise 2027 is more than just a change in barcode shape; it is a shift from static to dynamic data. Under the old 1D system, barcodes were often "pre-printed" because the information never changed. However, the 2D barcodes required for Sunrise 2027 are designed to carry variable data—real-time information that changes with every batch, shift, or even every individual package. Printing must now take place directly on the production floor during the packaging process.

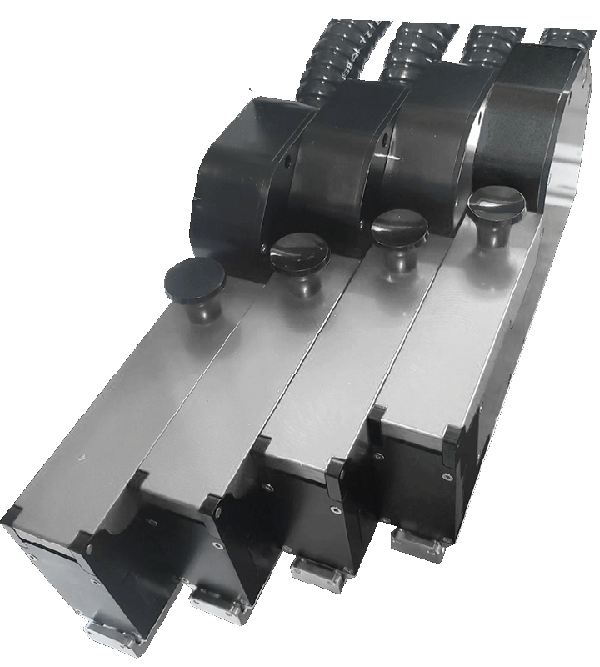

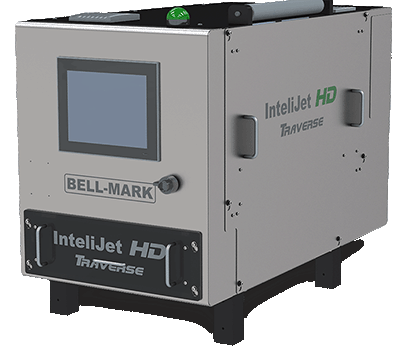

Engineered for Sunrise 2027: The BELL-MARK Advantage

BELL-MARK Digital Printers offer the most comprehensive solution to solve this challenge by providing key benefits required for Sunrise 2027 plus additional features to future-proof your packaging operation.

Real-Time Data Encoding

BELL-MARK Digital Printers seamlessly integrate real-time data directly into the 2D barcode during the packaging process. This on-the-fly encoding ensures that every individual unit carries the precise, live data required for modern traceability.

Waste Reduction

By printing on-demand, you eliminate the risk of obsolete, pre-printed packaging inventory when regulations or batch details change, ensuring your operation is as sustainable as it is compliant.

Code Precision and Integrity

The transition to 2D barcodes require a leap in printing precision; the density of a QR code leaves no room for error. BELL-MARK's Advanced Digital Printers guarantee high-contrast, high-resolution print quality, eliminating the risk of unreadable data and costly retail rejections.

Regulatory Future-Proofing

In an era of tightening food safety and traceability laws, the ability to generate unique, unit-level data in real-time is no longer optional. BELL-MARK's digital printing technology transforms this legal necessity into a competitive edge, ensuring you are prepared for both current and future regulatory shifts.